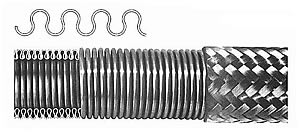

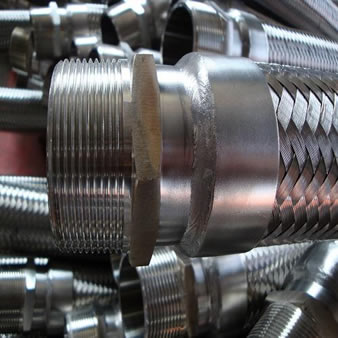

Metal hose also named flexible metal conduit is a high quality flexible pipe in modern industrial pipeline and it is more strong than flexible corrugated nylon conduits. It consists of corrugated hose, nets and connector. The inner corrugated hose made of stainless steel has helical and annular shapes. The nets are made of steel wire braided. It plays the reinforcement function. The connectors consist of screw thread, flange and quick coupling. All the connectors make it install easily and connected strongly. It is used as the compensation components, sealing elements, connecting elements and damping elements for gas, liquid transportation system and high temperature system.

Specification:

| Model | Hose I.D | Hose O.D | Minimum Bend Radius | Working Pressure (MPa) | |||

| Main Body | Single Braid | ||||||

| Inch | mm | mm | mm | mm | Single Braid | Double Braid | |

| HMH-6 | 1/4 | 6.3 | 9.0 | 10.5 | 150 | 6.4 | 10.0 |

| HMH-7 | 5/16 | 7.9 | 10.9 | 12.5 | 160 | 6.4 | 10.0 |

| HMH-10 | 3/8 | 10.8 | 15.2 | 16.8 | 180 | 5.0 | 8.0 |

| HMH-13 | 1/2 | 13.4 | 18.5 | 20.0 | 240 | 4.0 | 6.4 |

| HMH-16 | 5/8 | 16.0 | 21.5 | 23.0 | 300 | 3.5 | 5.0 |

| HMH-19 | 3/4 | 19.1 | 25.6 | 27.2 | 340 | 3.0 | 4.5 |

| HMH-25 | 1 | 25.4 | 32.6 | 34.2 | 400 | 2.5 | 4.0 |

| HMH-32 | 1-1/4 | 32.9 | 40.6 | 42.2 | 480 | 2.5 | 4.0 |

| HMH-39 | 1-1/2 | 39.3 | 47.6 | 50.2 | 600 | 2.5 | 4.0 |

| HMH-50 | 2 | 50.8 | 61.5 | 63.5 | 780 | 2.5 | 4.0 |

| Model | Hose I.D | Hose O.D | Minimum Bend Radius | Working Pressure (MPa) | |||

| Main Body | Single Braid | ||||||

| Inch | mm | mm | mm | mm | Single Braid | Double Braid | |

| AMH-14 | 1/2 | 14 | 20 | 22 | 120 | 7.5 | 12.5 |

| AMH-16 | 5/8 | 16 | 23 | 25 | 150 | 6.4 | 10.0 |

| AMH-20 | 3/4 | 20 | 28 | 35 | 180 | 5.0 | 8.0 |

| AMH-25 | 1 | 25 | 35 | 37 | 280 | 4.0 | 7.5 |

| AMH-32 | 1-1/4 | 32 | 43 | 45 | 340 | 3.5 | 6.4 |

| AMH-40 | 1-1/2 | 40 | 51 | 53 | 450 | 3.0 | 5.6 |

| AMH-50 | 2 | 50 | 62 | 64 | 550 | 2.5 | 4.0 |

| AMH-65 | 2-1/2 | 65 | 79 | 82 | 650 | 2.0 | 4.0 |

| AMH-80 | 3 | 80 | 97 | 100 | 800 | 2.0 | 3.2 |

| AMH-100 | 4 | 100 | 122 | 125 | 1000 | 1.6 | 2.5 |

| AMH-125 | 5 | 125 | 151 | 155 | 1200 | 1.5 | 2.5 |

| AMH-150 | 6 | 150 | 180 | 184 | 1500 | 1.5 | 2.5 |

| AMH-175 | 7 | 175 | 210 | 215 | 1750 | 1.2 | 2.0 |

| AMH-200 | 8 | 200 | 240 | 245 | 2000 | 1.2 | 2.0 |

| AMH-250 | 10 | 250 | 298 | 303 | 2200 | 1.0 | 1.6 |

| AMH-300 | 12 | 300 | 360 | 365 | 2500 | 1.0 | 1.6 |

| AMH-350 | 14 | 350 | 410 | 415 | 3000 | 0.8 | 1.2 |

| AMH-400 | 16 | 400 | 460 | 465 | 3500 | 0.6 | 1.0 |

Feature:

Application:

Metal hose is widely used to transport air, smoke, liquid gas, all kinds of industrial gas. Also used for steam transfer, water, oil, food process, chemical and high temperature installations.

Inquiry for Our Product

Hebei Qianli Rubber Products Co., Ltd.

E-mail:

goff@hebeiqianli.com

When you contact us, please provide your detail requirements. That will help us give you a valid quotation.